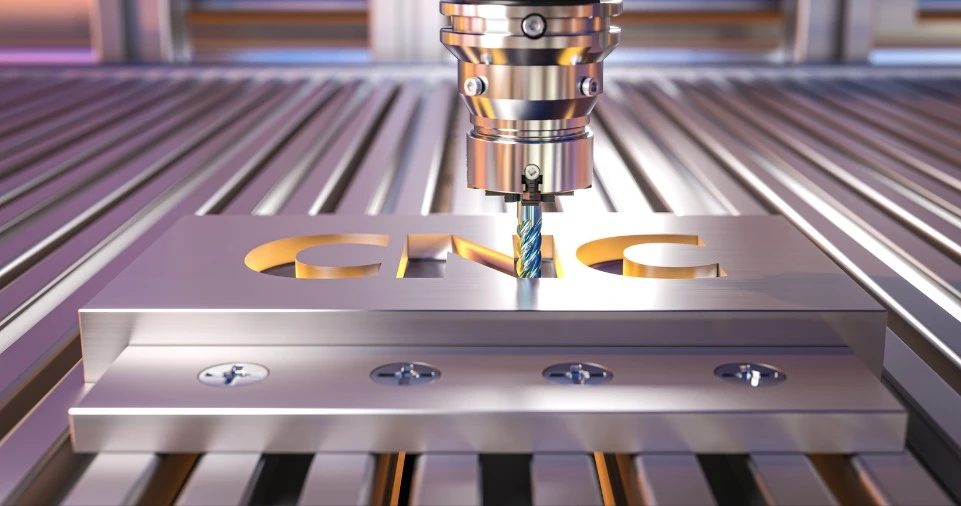

Aluminum is one of the most versatile and widely used materials in industries ranging from aerospace to automotive, electronics, and medical devices. Its lightweight nature, combined with high strength, corrosion resistance, and ease of machining, makes aluminum an ideal choice for manufacturing both prototypes and production runs. In this context, the role of CNC machining (Computer Numerical Control) has become essential for delivering precise, high-quality components in a time-efficient manner.

As manufacturing processes continue to evolve, the need for more efficient and rapid production methods grows. Rapid Axis technology has emerged as a critical player in improving the efficiency and precision of CNC machining, especially when dealing with aluminum. By understanding the applications, advantages, and role of Rapid Axis in aluminum CNC machining, businesses can make informed decisions when choosing this process for their prototyping and production needs.

The Importance of Aluminum in CNC Machining

Aluminum has long been a favorite material for CNC machining because it balances many desirable properties. It is lightweight, has good thermal and electrical conductivity, and is non-corrosive when treated properly. Aluminum is also easier to machine compared to other metals like steel or titanium, which makes it an excellent choice for both rapid prototyping and mass production.

When it comes to CNC machining, the primary benefits of aluminum are its machinability and the ability to achieve tight tolerances, even on complex geometries. This is crucial in industries such as aerospace, where precision is paramount for components like brackets, housings, and enclosures. Moreover, aluminum’s adaptability allows manufacturers to create intricate, high-precision parts in a timely and cost-effective manner.

The Role of CNC Machining in Prototyping

Prototyping is an essential stage in the product development cycle. Engineers, designers, and manufacturers rely on prototypes to test and validate designs before proceeding to full-scale production. CNC machining, particularly when applied to aluminum, is ideal for this purpose because it allows for rapid creation of accurate and functional prototypes.

In the past, producing prototypes required casting or other traditional manufacturing methods, which could be time-consuming and costly. However, with CNC machining, manufacturers can quickly generate complex geometries from a digital design file, such as a CAD (computer-aided design) drawing, which is then converted into machine instructions. This process eliminates much of the labor-intensive work associated with traditional prototyping techniques. Additionally, aluminum’s light weight and ease of handling help streamline the prototyping process.

A critical benefit of using aluminum in CNC prototyping is that prototypes made from this material often closely mirror the final product. This makes it easier to evaluate functionality, aesthetics, and other design features before moving into mass production. As engineers can test real-world performance during the prototyping phase, they can catch potential issues early in the process, ultimately saving both time and money.

CNC Machining for Production Runs

While prototyping is a key part of product development, production runs are where CNC machining truly shines. Once a prototype has been validated, manufacturers need to produce parts in larger quantities for distribution or assembly into final products. Here again, aluminum’s combination of machinability and strength comes into play. With CNC machining, manufacturers can create high volumes of parts with consistent quality and tight tolerances, meeting the specific requirements of industries like aerospace, automotive, and medical devices.

One of the major advantages of using CNC machining for production runs is the ability to replicate the same high-quality parts across a batch. CNC machines are programmed to follow precise instructions, ensuring that every piece is made to the same specifications, regardless of how many parts are being produced. This level of consistency is difficult to achieve with traditional methods, such as casting or manual machining.

Furthermore, CNC machining for production runs can be automated to a large extent, reducing the need for human intervention and further improving efficiency. The ability to produce large quantities of aluminum parts quickly and accurately is essential in industries where time to market is critical.

The Role of Rapid Axis in CNC Machining

The introduction of Rapid Axis technology into the CNC machining process has had a profound impact on both prototyping and production runs, especially in the context of aluminum machining. Rapid Axis refers to high-speed, multi-axis CNC machines that can move in several directions simultaneously. These machines are designed to execute complex operations with minimal downtime, greatly reducing machining time and improving the speed of production.

In the traditional CNC machining process, machines typically operate along three linear axes (X, Y, and Z), meaning that the cutting tool can only move along those three directions. Rapid Axis CNC machines, however, incorporate additional rotational axes, allowing the tool to move in more intricate patterns and angles. This increased flexibility leads to faster processing times and the ability to machine more complex shapes with fewer setups. For aluminum machining, this is particularly valuable, as it helps reduce the amount of time spent adjusting the part, which is often a bottleneck in traditional machining processes.

By integrating Rapid Axis technology into the machining process, manufacturers can reduce lead times significantly, especially when producing intricate, multi-featured parts. This is crucial when time-sensitive projects require fast turnaround times for prototyping and small or medium production runs. Moreover, Rapid Axis machines improve the overall quality of aluminum parts by reducing the risk of errors that can occur during manual adjustments or multi-step machining operations.

The Benefits of Rapid Axis in Aluminum CNC Machining

The use of Rapid Axis in CNC machining offers several key advantages for both prototyping and production runs. These include:

1. Increased Precision and Complexity

With the ability to operate along multiple axes, Rapid Axis machines can achieve higher precision when working with aluminum, especially on complex or intricate designs. The ability to perform multiple machining operations without re-fixturing the part ensures that each feature is cut precisely, with fewer chances for error.

2. Faster Production Times

Rapid Axis machines reduce setup times by eliminating the need for multiple setups. This results in faster cycle times and, in turn, quicker production runs. By minimizing downtime and reducing the time spent on manual adjustments, manufacturers can significantly reduce lead times.

3. Reduced Tool Wear

The precision and speed of Rapid Axis machining also contribute to reduced tool wear. The continuous, smooth motion of the tools helps maintain their sharpness and longevity, ultimately reducing costs related to tool replacement and maintenance.

4. Improved Surface Finish

The multi-axis capabilities of Rapid Axis machines allow for smoother tool paths and reduced chances of part deflection or vibration during machining. As a result, the final aluminum parts have a superior surface finish, which is especially important for applications requiring a high level of aesthetic or functional performance.

Future Trends in Aluminum CNC Machining

As manufacturing technologies continue to advance, the combination of aluminum CNC machining and Rapid Axis is likely to play a central role in future developments. The rise of automation, AI integration, and the increasing availability of advanced materials will further enhance the capabilities of CNC machining. Moreover, the demand for more sustainable production processes will drive innovations that make aluminum machining even more efficient, cost-effective, and environmentally friendly.

In the coming years, we can expect to see continued advancements in Rapid Axis technology, allowing for even more intricate and complex designs to be produced at faster rates. The synergy between aluminum and CNC machining, particularly with the incorporation of rapid axis systems, will remain crucial for industries demanding high-quality, precise parts, and rapid production cycles.

Conclusion

Aluminum CNC machining is a cornerstone of modern manufacturing, offering a reliable, efficient, and precise method for producing both prototypes and full production runs. The integration of Rapid Axis technology into CNC machining processes has revolutionized the industry by providing faster production times, greater precision, and the ability to produce more complex parts. As industries continue to demand higher-quality components and quicker turnarounds, the role of Rapid Axis in aluminum machining will only grow in importance. Whether for rapid prototyping or large-scale production, the combination of aluminum and Rapid Axis technology provides manufacturers with the tools they need to stay competitive in an increasingly fast-paced and demanding market.